Technology Recognized by the Korean Ministry of Environment

Selected as the finest technology for the top environmental technology development project worldwide (Ministry of Environment, Korea Environmental Industry & Technology Institute, Innovative product certification in 2021)

- Energy efficiency analysis and energy demand forecasting error rate: Achieved within 5%

- Achieved 25% reduction in aeration energy in the wastewater treatment process

- Effluent water quality prediction error rate: Achieved within 5% (based on total nitrogen)

- IoT sensor error rate: Achieved within 5%

Biological Process Diagnostics with MassFlow Live Online

MassFlow Live provides online simulation and decision-making information for wastewater treatment processes without operator intervention.

- Server in connection with the database automatically simulates wastewater treatment process every hour

- Automatic correction of steady-state simulation results, automatic analysis of dozens of scenarios

- Provides visualization functions that are easy to understand even for non-experts

- Energy efficiency analysis and solid retention time analysis

- Cluster analysis, histogram analysis and operation status analysis using past operation data

- Heat map for long-term operation diagnosis status viewing

- Easy user editing of key features such as screen layout, colors, etc.

- View results in desktop or mobile

Reduce analysis costs with MassFlow ICM influent characterization tool

MassFlow ICM (Influent Characterization Method) uses the Harmony Search method, one of the representative optimization algorithms, to analyze organic substances and nitrogen and phosphorus properties in the influent. In the past, characterization was performed in the laboratory, but now MassFlow ICM enables cost-effective and reliable simulations.

- Analysis of biodegradability, recalcitrance ratio, and C/N ratio in influent

- Long-term (months to years) analysis of influent sewage properties

- Analysis of water quality change patterns by month and day of the week

- Analysis of current influent water quality using clusters and histograms

- Event transmission under various conditions such as increasing the recalcitrance ratio and decreasing the C/N ratio

Discharged Water Quality Early Warning System using MassFlow EWS AI

MassFlow EWS (Effluent Warning System) applied self-supervised learning algorithm using smart sensor and existing water quality TMS data. Artificial intelligence (AI) technology predicts discharged water quality with high reliability without operator intervention and provides information for operators to respond flexibly.

- Prediction of discharged water quality using AI and ensemble model (up to 24 hours later)

- Learning and error correction using a self-supervised learning algorithm

- Step-by-step alert notification to the operator (text message, e-mail, WhatsApp)

MassFlow EOS Aeration Energy Saving System

MassFlow EOS (Energy Optimization System) is a system that optimizes the use of blowers, which account for the highest energy use in sewage treatment plants.

- Optimal control of aeration by analyzing inflow load and treated water quality

- Provides a control mode applicable to various sewage treatment processes such as continuous and batch processes

- Evaluation of aeration energy consumption using KPI (Key Performance Indicator) indicators

- PLC operation control mode for safe aeration control

- Analysis of energy and greenhouse gas savings

MassFlow CCS Optimized Chemical Control System

MassFlow CCS (Coagulant Control System) is a system that controls the inorganic coagulant and external carbon sources in the total phosphorus removal facilities in the wastewater treatment process. It helps to reduce the excessive use of chemicals but also, when necessary, increase the amount of chemicals to maintain a stable level of water quality.

- Automatic control of inorganic coagulant used in total phosphorus facility with water quality TMS and smart sensor

- Automatic control of external carbon sources in connection with the influent property analysis system

- Stable control of treatment process in connection with effluent quality warning system

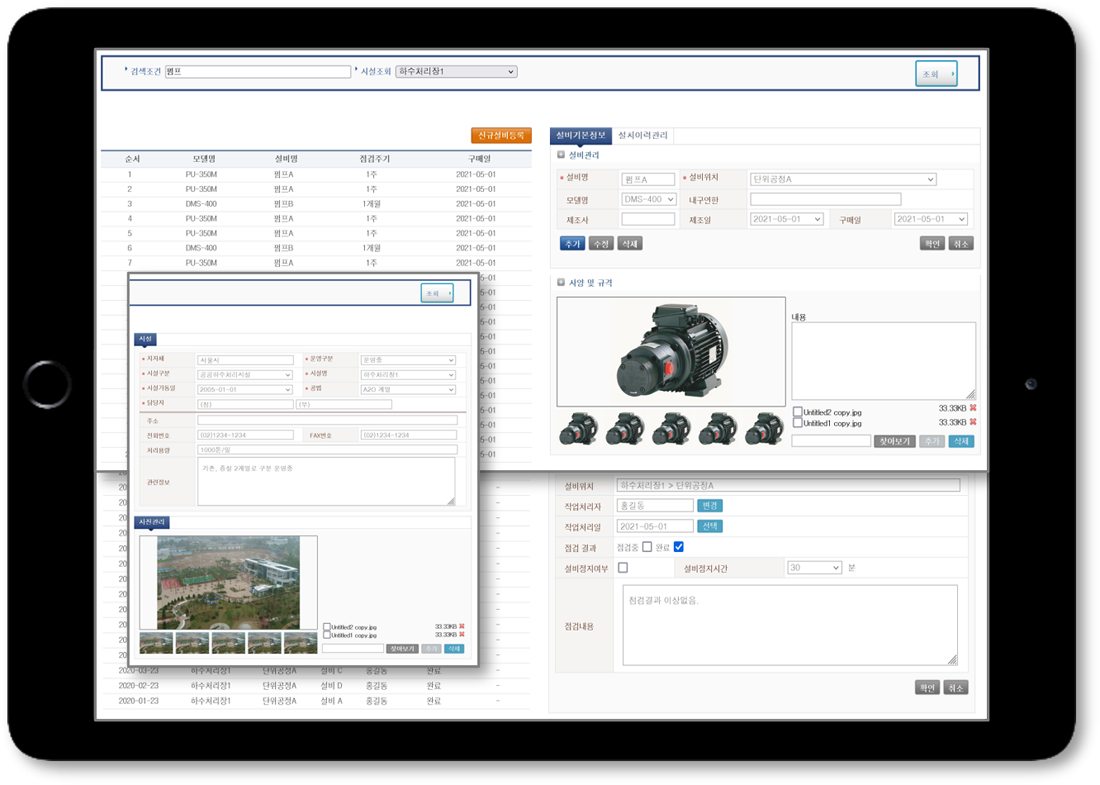

MassFlow FMS Facility History Management Software웨어

Facility history management software MassFlow FMS (Facility Management System) is a cloud-based asset management system.

① Print QR code (including URL information)

② Attach QR code (using coated paper 32 mm X 32 mm)

③ Scan QR code (use smartphone scan function)

④ View and modify (Log in to FMS website)

- Integrated asset management of multiple facilities in a cloud environment

- Use on smartphones, tablets and desktop PCs without installing a separate program (using a web browser)

- Authorization of access according to administrator account, registration and update of assets using QR code

- Research and manage asset maintenance history, reduce initial data construction time by uploading existing data using Excel files

- Real-time asset monitoring in conjunction with MassFlow EMS

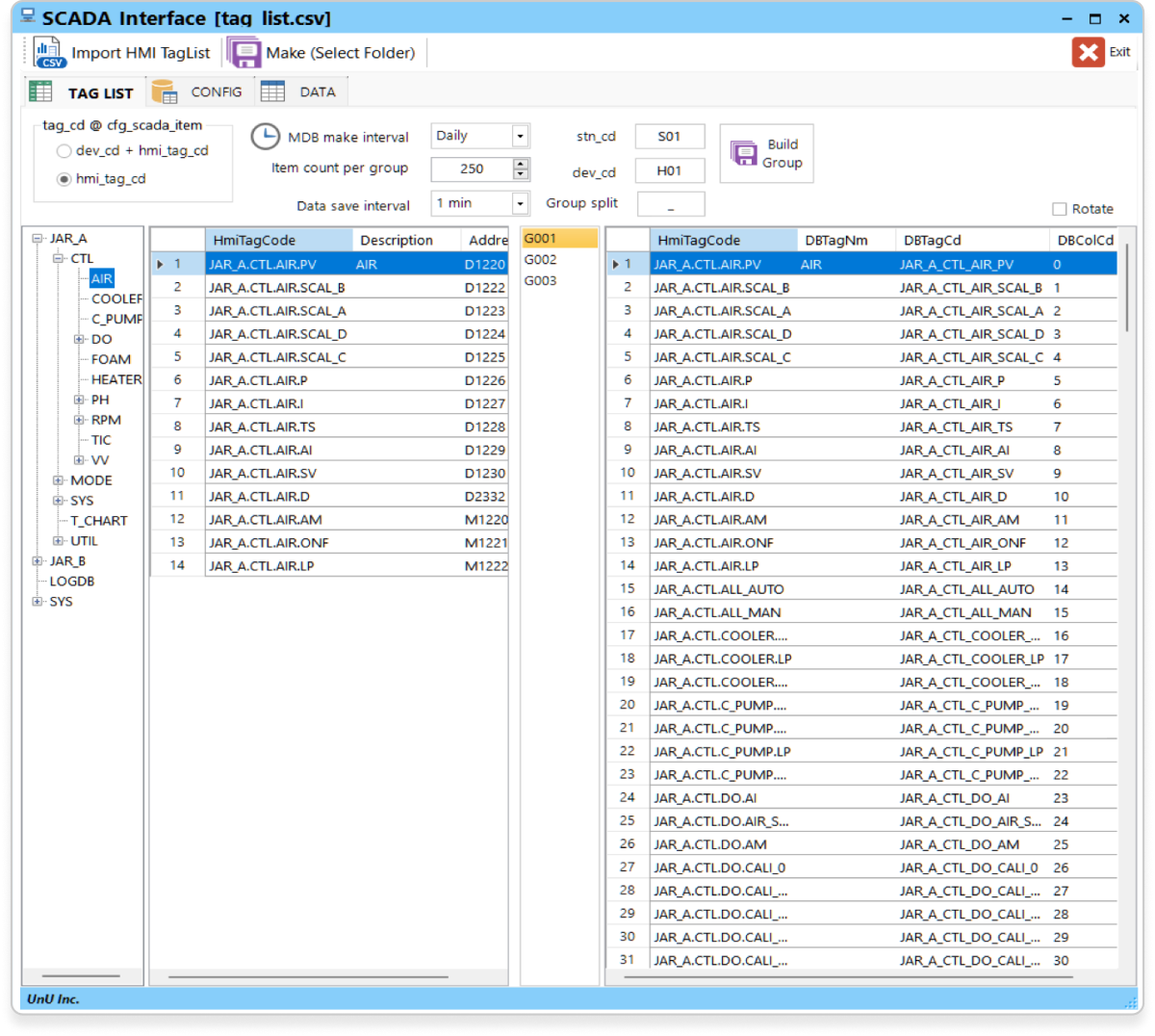

MassFlow SIF SCADA Interface System

The SCADA interface system stores the currently operating SCADA system measurement data and smart sensor measurement data as a smart solution database.

- Supports various linkage methods to collect data from SCADA systems that have already been built and operated

- Communication CIMON HMI real-time data collection

- PLC linked data collection

- OLEDB and OPC communication data collection - Supports various databases such as MS Access, PostgreSQL, and MS-SQL for data storage and management

- Real-time collection of smart sensor data through serial and Ethernet communication methods

MassFlow EMS Efficient and Economical Power Monitoring System

MassFlow EMS (Energy Management System) analyzes the integrated watt-hour meter information and equipment operation time and predicts the electricity usage status in sewage treatment facilities. By applying the device uptime analysis method, it is possible to reduce the installation cost of the integrated watt-hour meter and provides information on the usage life of the device.

- Digital watt-hour meter installation and data collection for major loads

- Power consumption analysis by process, KPI indicator analysis

- Monthly, daily, and weekly electricity usage analysis

- Power consumption analysis through device uptime analysis

- Sending an alarm to the operator before the service life is reached through facility uptime analysis

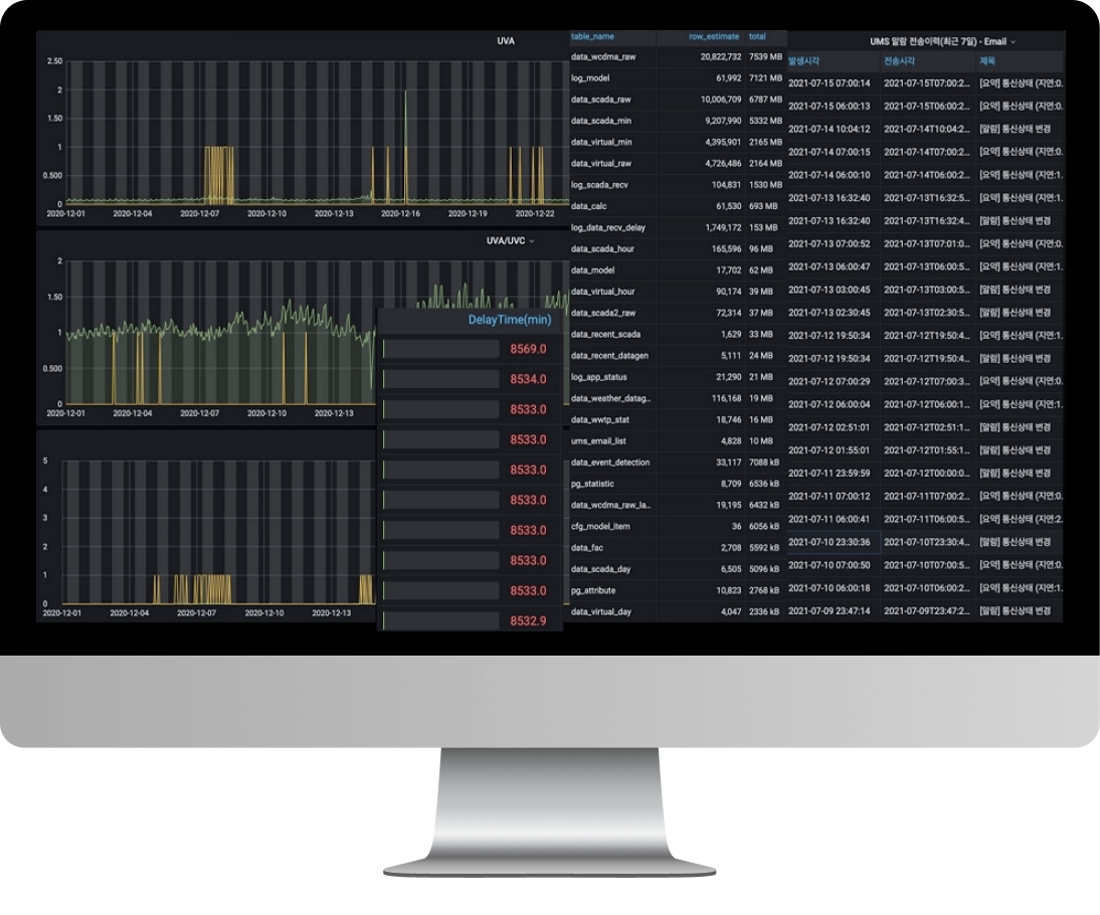

MassFlow DBS Integrated Data Management System

MassFlow DBS (Database System) is a software for managing data collected from wastewater treatment plants and viewing analysis results in a cloud environment.

- SCADA interface software for data acquisition from SCADA systems

- Integrated messaging software (UMS) for sending email, text message, and WhatsApp messages

- Operator account management software

- Data preprocessing software (noise filtering, sensor abnormality detection)

- Network security system

- Open platform-based visualization software

- Open platform-based database

MassFlow Wastewater Treatment Plant Simulation Software

MassFlow is a desktop simulation software for wastewater treatment plant process simulation based on IWA ASM2d and ADM1. Plant-wide simulation of the full-scale water treatment plant can be performed using measured and laboratory operation data collected in the field.

MassFlow

The Grafana and PostgreSQL images used on this website (or documentation) are examples and are not included in the UnU solution.

Grafana is trademarks of Grafana Labs. PostgreSQL is trademarks of PostgreSQL Community Association of Canada.

Start MassFlow Smart Now.

| Basics | Optional | |

|---|---|---|

| Smart Sensor (Influent) TOC, COD, SS, T-N, T-P, Water temperature |

|

|

| Smart Sensor (Bioreactor inflow) TOC, COD, SS, T-N, T-P, Water temperature |

|

|

| Smart Sensor (Effluent) TOC, COD, SS, T-N, Water temperature |

|

|

| Integrated Data Management Software (MassFlow SIF, DBS, UMS) |

|

|

| Water Quality Prediction Software (MassFlow EWS) |

|

|

| Process Diagnosis Software (MassFlow Live) |

|

|

| Simulation Software (MassFlow3) |

|

|

| Aeration Energy Saving Software (MassFlow EOS) |

|

|

| Facility History Management Software (MassFlow FMS) |

|

|

| Energy Management Analysis Software (MassFlow EMS) |

|

|

| Chemical Control Software (MassFlow CCS) |

|

|

| Carbon Footprint Analysis Software (MassFlow ESG) |

|