Software quality certification according to

Article 20 of the Software Promotion Act

MassFlow is a software with the highest level of Good

Software and holds 6 related technology patents.

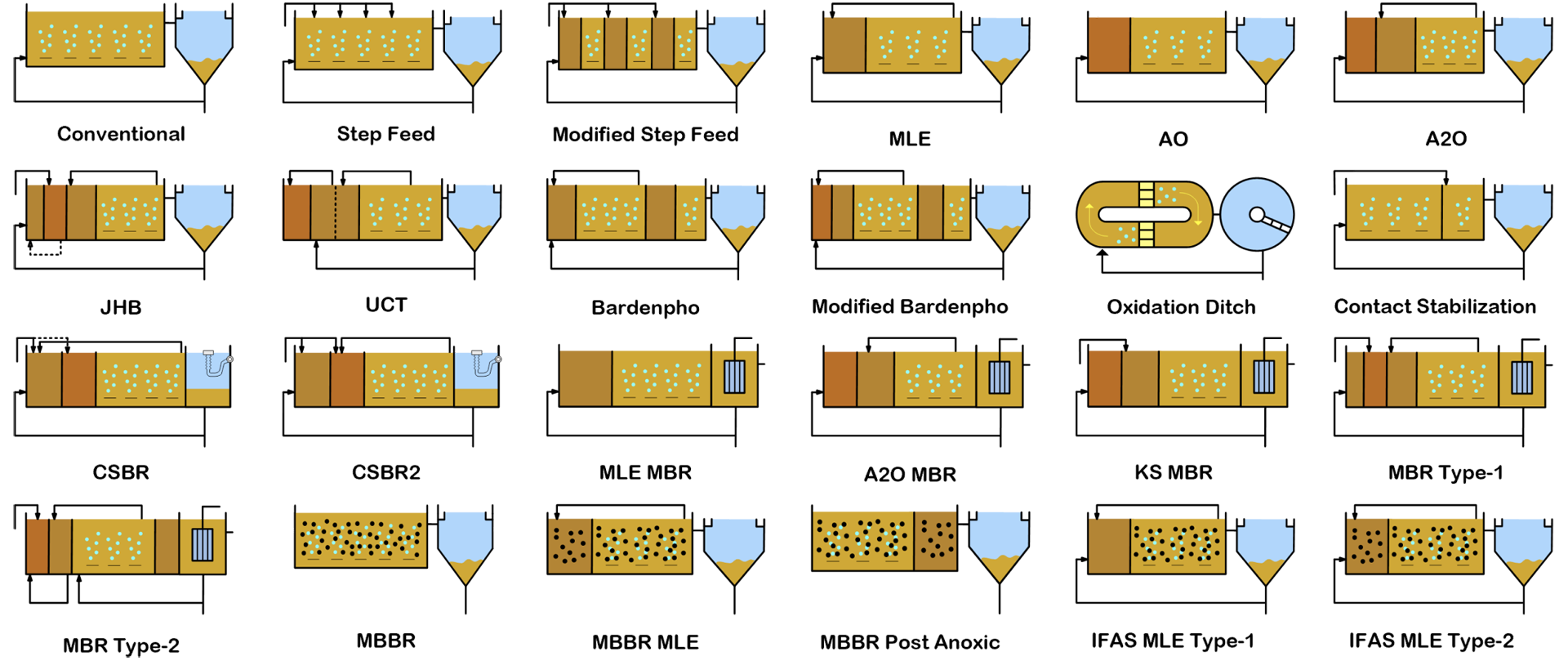

Various Wastewater Treatment Processes

- Standard activated sludge, A2O, MLE, Bardenpho, Oxidizer, MBR, MBBR, IFAS, etc. Dozens of types of activated sludge processes that can be combined

- Anaerobic Digestion and Aerobic Digestion, UASB

- Biological Filtration (BAF), High-Rate Filtration, Denitrification Filter, Trickling Filter, AMX, Lagoons, Rotating Disc (RBC), Aerobic Granular Sludge (AGS)

- Gravity sedimentation, gravity concentration, filter, flow control tank, screen, pressurized flotation tank (DAF), thermal hydrolysis, disinfection, RO, advanced oxidation, sludge drying bed, dryer, black box model

Various Water Quality Simulations

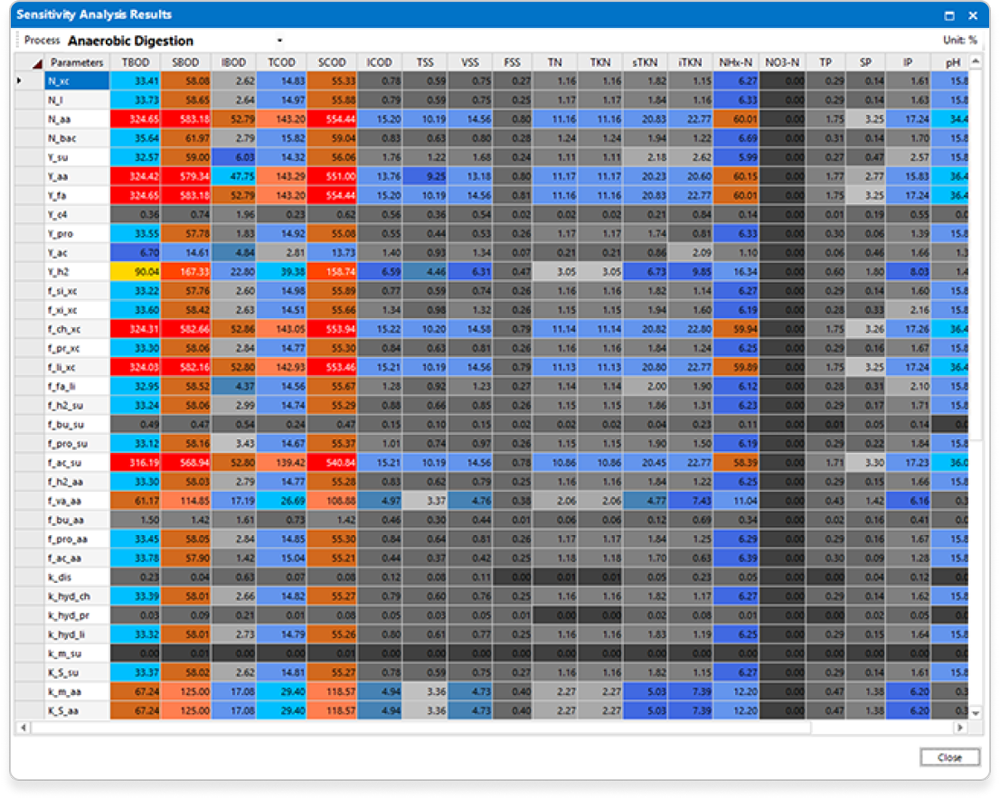

- Steady-state and dynamic simulation of over 50 substances including organic substances and nutrients

- Organic substances: BOD, IBOD, SBOD, COD, SCOD, ICOD, TOC, TSS, VSS, FSS, CODmn, 5 user-defined substances (3 dissolved substances, 2 particulate substances)

- Nutrients : TN, TKN, STKN, ITKN, NHx-N, NO3-N, NO2-N, TP, SP

- Hydrogen ion concentration, alkalinity, water temperature, Dissolved Nitrogen Gas, Metal Hydroxide Compounds, Metal Phosphorus Compounds, etc.

Optimal Modeling and Design Support

- Applying a numerical analysis solver (Hybrid Newton’s Method) that is 100 times faster than the conventional ordinary differential equation solver

- Sensitivity analysis tool provided

- The amount of nutrients removed during the nutrient removal process is calculated

- Calculation of coagulant usage and analysis of chemical sludge generation

- Analysis of clarifier sludge concentration profile (when Double Exponential model is applied)

- Calculation of AOTR, SOTR, load, and wattage required for air supply to the bioreactor

- Analysis of Biological Nitrogen and Phosphorus Synthesis

- Checklist generated by comparing design recommendations and user editing

- Screen report for displaying and dynamically updating simulation results on layout

- Calculation of chemical cost, sludge treatment cost, area required for a treatment facility, air volume, and power consumption

- Preset editor for dynamic simulation

- Generate a report as a Microsoft Excel file

- Stay up to date with online updates

Optimization Function for Intelligent Wastewater Treatment Plants

- Determination of optimal oxygen supply by exploring the relationship between treated water quality and dissolved oxygen concentration

- Investigation of treated water quality and concentration of microorganisms in the reaction tank according to the change in the amount of surplus sludge produced in the activated sludge process

- Establishment of monthly and seasonal plant operation strategy

- Establishment of automatic control strategy based on daily oxygen consumption and aeration rate by the bioreactor both hourly and daily

- Provides inflow sewage pattern presets such as high load, low load, and high flow rate for dynamic simulation

- Evaluation of optimal injection amount using automatic control model for chemicals and solids retention time

- Control of air volume and chemicals in conjunction with on-site PLC and HMI

- Provides SCADA Interface for process automation

- Automatic simulation and process diagnosis on the server

- Storing and managing process diagnosis results in DBMS, and sending an alarm when an error occurs (e-mail, text message, WhatsApp, etc.)

- Supports various databases such as MS-SQL, Oracle, PostgreSQL, etc.

- Remote access using a web browser and support for the mobile environment

Learning Videos

-

1. MassFlow3 Introduction

-

2. Starting MassFlow3

-

3. MassFlow3 activated sludge process setup

-

4. MassFlow3 SBR Setup

-

5. MassFlow3 BAF Setup

-

6. MassFlow3 On-Screen Report Creation